Common Spring Finishes

| Electroplating | Oxidation/phosphating treatment | Painting | Other Treatments |

|---|---|---|---|

| Zinc Plating(Zn) | Black Oxide | Powder Coating | Ultrasonic Cleaning |

| Nickel Plating (Ni) | Phosphating | Electro-deposition Coating (ED) | Passivation for Stainless Steel |

| Tin Plating (Sn) | Geomet ® 720 | Electro-polishing (EP) | |

| Chrome plating (Cr) | Vibratory finishing (tumbling) | ||

| Gold plating (Au) | |||

| Silver plating (Ag) | |||

| Copper Plating (Cu) |

Types of Finishes

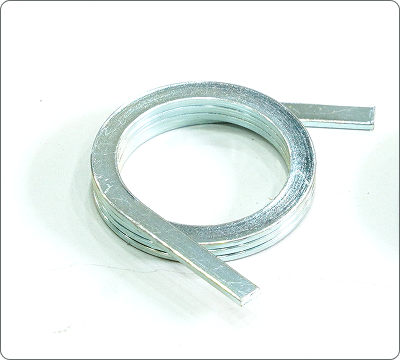

Zinc Plating

Galvanizing is one of the most common metal surface treatment methods, mainly used to prevent corrosion of steel and iron materials. The surface of electro-galvanizing is glossy and suitable for automotive parts, screws, spring hardware, etc. The galvanized layer can be further passivated (such as blue passivation, yellow passivation) to improve corrosion resistance.

◎ Blue Zinc Plating

It appears bluish white and is usually treated with a blue or white passivation after galvanizing. The rust resistance is moderate.

◎ Colored (Yellow) Zinc plating

The zinc layer is treated with colorful passivation to present a variety of colors such as rainbow colors, and its anti-rust effect is higher than that of blue-white zinc and black zinc. As environmental regulations become more stringent, trivalent chromium (Cr 3+) has been used in the production process of colorful zinc to replace hexavalent chromium (Cr 6+).

◎ Black Zinc Plating

The surface is black, providing basic anti-corrosion function, but the protective effect is slightly weaker than blue-white zinc and colorful zinc.

Oxidation/phosphating

Black Oxide

Black oxide is a conversion coating that provides a thin, protective layer on metal surfaces, typically steel, stainless steel, and copper alloys. This process creates a black, aesthetically appealing finish while providing moderate corrosion resistance. Black oxide finishes do not add significant thickness to the part, making it ideal for applications where dimensional precision is critical. Additionally, it offers minimal wear resistance but can be combined with oils or sealers for enhanced protection.

Phosphating

Phosphating is a process where a metal surface is coated with a phosphate layer, typically zinc or manganese phosphate, through a chemical reaction. This finish improves corrosion resistance and acts as a base for further coatings like paints. Phosphating also enhances the adhesion of lubricants or oils, making it useful for parts requiring lubrication during operation. The phosphate layer provides a durable, matte surface that offers excellent wear resistance, making it commonly used in automotive, machinery, and military applications.

Both finishes are widely used in industries requiring corrosion resistance, durability, and lubrication properties.

Painting

Powder Coating

Powder coating uses powdered paint, which is uniformly sprayed onto the metal surface through a spray gun under the effect of an electrostatic field. The coated metal is then heated to a certain temperature to melt and cure the powder, forming a strong coating. The coating is hard, wear-resistant, scratch-resistant, and has good corrosion resistance. However, the thickness of the coating may affect the final size of the spring.

Electro Deposition (ED) Coating

A method that uses electrophoresis technology to evenly attach water-based paint to the metal surface. This coating method offers good corrosion resistance, and the coating is more uniform than powder coating, especially suitable for complex-shaped metal parts. However, in terms of wear resistance, electro deposition coating is relatively weaker.

GEOMET®

A highly effective lead-free corrosion-resistant metal surface treatment that combines multi-layer zinc-based materials with organic substances to provide excellent corrosion resistance, wear resistance, and anti-friction performance. It is mainly applied to long-lasting parts such as automotive, mechanical parts, and other metal components

Characteristics of Finishes

| Corrosion Resistance |

Wear Resistance |

Heat Resistance |

Cost | Characteristics & Applications |

|

|---|---|---|---|---|---|

|

Zinc Plating (Blue/color/black) |

Good |

Limited Easy to scratch |

Limited | Low | Goodcorrosion resistance, low cost, and durability. Commonly used in screws, springs and hardware. |

| Nickel Plating(Ni) | Good | Good | Good | Medium | High Wear &corrosion resistance, typically used for decorative purposes. |

| Tin Plating (Sn) | Good | Limited | Limited | Low | Excellent solderability and conductivity. Used in electronics and electrical components. |

| Chrome plating(Cr) | Excellent | Excellent | Excellent | High | High Wear &corrosion resistance, typically used for shiny decorative purposes. |

Appearance and color

-

Plain/ No finish

-

Black Oxide

-

Powder Coating (Red color)

-

Colored (Yellow) Zinc plating

-

Blue Zinc Plating

-

Nickal Plating