Production Capabilities

-

Professional OEM/ODM Spring maker

MK SPRING is a dedicated manufacturer of springs with vast OEM/ODM customized production experience. We keep a close watch on every step of the production process, starting from design, drawing , to sample making, production, final inspection and shipment. The result is a product of the highest quality.

- Extensive Product Range: Focus on diverse range of spring products

- ISO 9001:2015 certified

- Familiar with automotive industry demands such as PPAP Level 3 documentation

-

Design assistance: Listen to Customer

MK SPRING always insists on personal contact with customers in order to fully understand their requirements. In what environment will a spring be used? What is the frequency of use? How and where will it be assembled into a final product? Understanding these issues and more allows us to meet or exceed the strict demands of our customers.

- Complete technical (design) assistance

- Problem solving with your engineers in design and prototyping

-

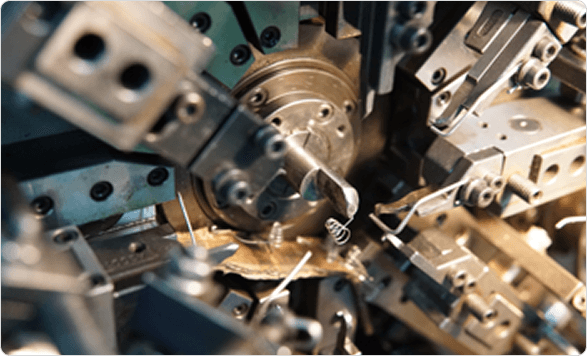

Precise & Streamlined making processes

- Multi-Axes fully automated CNC spring coiling/bending machines available

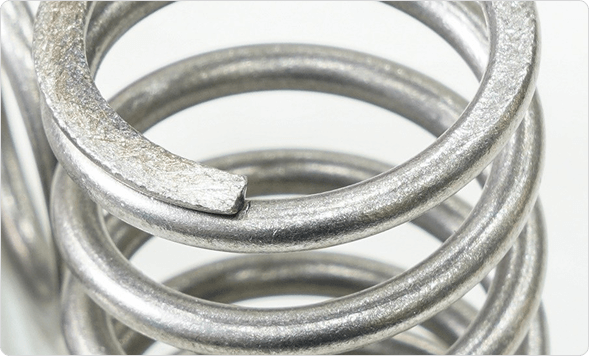

- All processes streamlined In-house: forming, heat treatment, grinding, and shot peening.

- Wire diameter range from 0.1mm up to 6.0mm (0.004” to 0.236”) ; Strip thickness range from 0.1mm up to 1.0mm (0.004” to 0.04”)

- No tooling cost in spring forming process

-

Short Production Cycle & Delivery

We offer short production cycles and on-time delivery with worldwide shipping options. Our production capacity ensures quick turnarounds for high-demand orders, and we support Vendor Managed Inventory (VMI) for streamlined supply chains.

With full control over production, we guarantee local sample delivery within 3-7 days and volume shipments within 2 weeks, providing efficient and reliable service to meet your needs.

※ Overseas delivery times depend on shipping schedules -

Lot Traceability

We ensure lot traceability for every batch. All products will display the part number and lot number on the packaging, making them traceable to the materials and processes used to manufacture your parts.

Manufacture and processing processures of spring

-

Spring Forming

-

Spring Ends Grinding

-

Shot Peening

-

Spring Tempering