Quality & Testing Capabilities

-

Applying end-to-end quality control

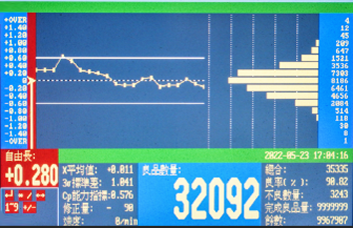

Applying end-to-end quality controlWe apply Statistic Processing Control (SPC) in making processes to make sure every spring is of the highest quality

-

Precision Testing Equipment and Product

Quality Assurance

Precision Testing Equipment and Product

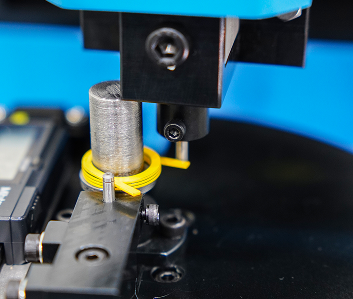

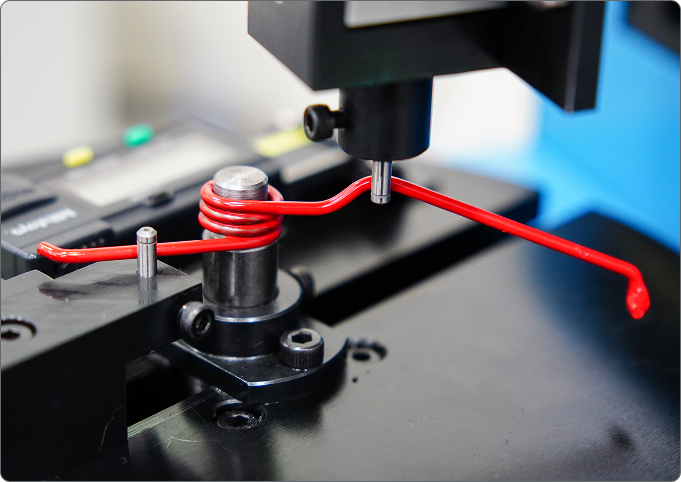

Quality AssuranceTo ensure that every spring meets stringent quality standards, MK SPRING utilizes advanced precision testing instruments, including spring load testing equipment.

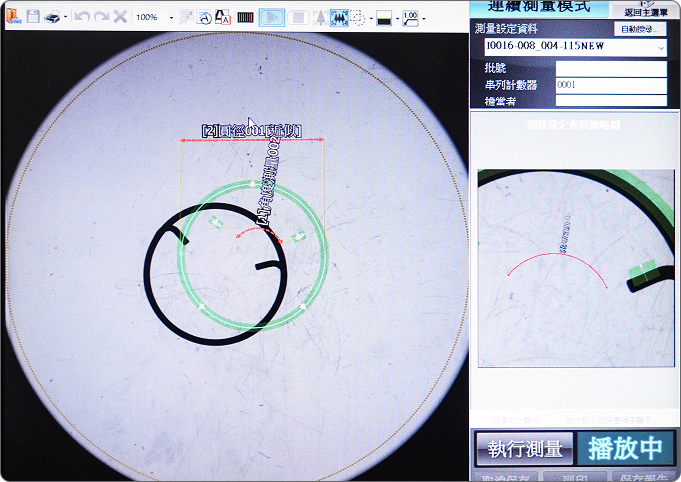

This technology accurately measures deformation and load-bearing capacity under various conditions, verifying that each spring performs according to design specifications. Additionally, all springs undergo thorough dimensional and performance testing to guarantee consistency and long-term stability. -

Durability and Life Testing

Durability and Life TestingA specialized durability testing mechanism is used to conduct life tests on the product, simulating various working conditions the spring may encounter over long-term use. This ensures that it consistently maintains excellent performance and reliability, even under extreme conditions.

-

Eco-Friendly Manufacturing

Eco-Friendly ManufacturingWe promise that raw materials and products do NOT contain hazardous substances restricted by EU RoHS 2.0 & REACH regulations.

Testing services

| Item | Content | Description |

|---|---|---|

| Raw Material Control | Material certificate by material supplier | Using raw material from Taiwan, South Korea, Japan, United States, UK and Germany. |

| Functional Testing | Spring Load:spring load testing | Measure spring pressure, tension and torque according to the type of spring, ranging from 1gf to 500kgf |

| Fatigue Resistance:spring life cycle testing | According to customer needs, set the frequency and number of cycles to test the spring life and check whether it is fatigued or broken. | |

| Corrosion Resistance:Salt spray testing, coating thickness testing | According to ASTM B117 standard, the corrosion resistance of the spring is tested with neutral salt spray. | |

| Environmental Requirements | Hazardous substances test report & declaration

| We promise that raw materials and products do NOT contain hazardous substances restricted by EU RoHS & REACH regulations |

| Regulation Compliance |

|

We ensure all exports comply with international regulations, following the required customs, documentation, and safety standards for a smooth, efficient, and compliant shipping process. |

| Quality Documents | PPAP Level 3 | PPAP Level and other quality documents are available upon request |

-

Load Testing for Compression Spring

-

Load Testing for Torsion Spring

-

Load Testing for Tension Spring

-

Dimension Inspection